Yaran Bahar-e Golestan Co

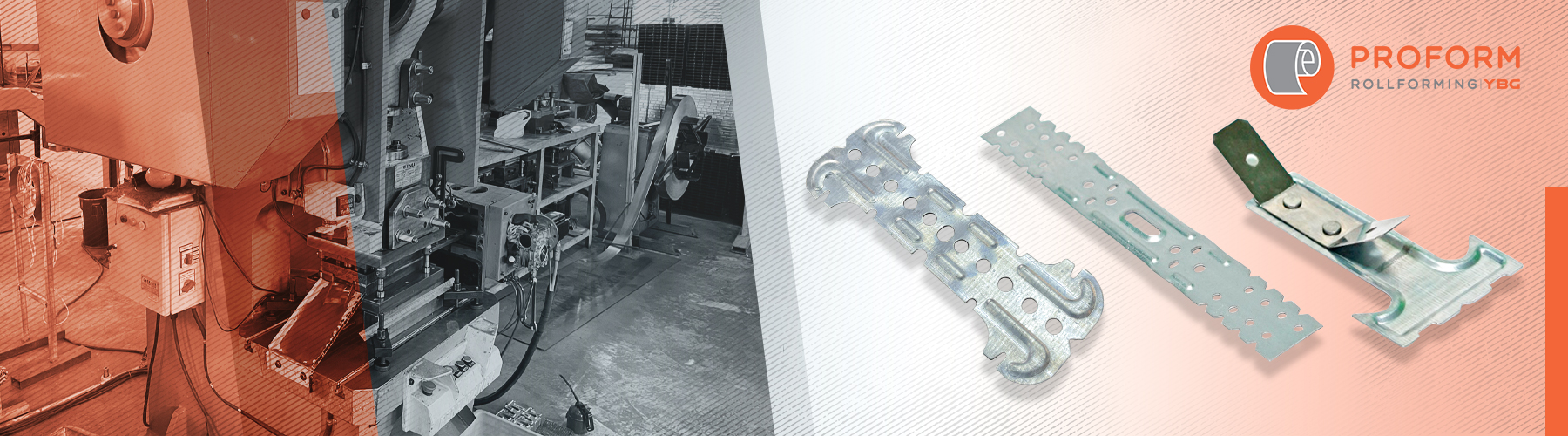

Roll forming is one of the most common methods of shaping metal sheets. In this method sheets take the desired shape after passing some reels along their way. This system which is based on the functions of roll forming machine, is one of the most common methods of shaping metal sheets. In this method, the reels give the desired shape to the sheets during various stages in a cold manner to produce the desired profile.

In Roll forming method, the bindings and angles imposed on the sheets at different stages of forming, should apply the lowest stress on the produced sheets or profiles so that desirable and admirable structures may yield, and the possibility of change may be reduced to minimum on long sheets.

The number of stages or so called stations of roll forming machines depends on the type of sheet, its form and thickness and the complexity of the structure’s angle. The speed of profile production should be the same in various stages to prevent the elongation of sheets. Therefore the templates should be designed in a way that this principle is applicable on them

It doesn’t matter to what extent the produced profiles’ sections are standard in terms of size and angles, it is important that the produced section has no bending and twisting at the time it is going to convert into profiles in various lengths. In addition, construction, automotive, and household appliances profiles, as well as production of required storage racks and lighting appliances, are among the applications of metal forming method. This method is widely used in the construction industry and our company, with advanced equipment of roll forming industry, manufactures and markets Pro.Form-YBG brand materials for different construction application.

Our Products

Light weight structure frame

Light Steel Frame Building Systems (LSF)Light weight steel frame prefabricated buildings that are called LSF constructions and are used in rigid form and mostly with screw connections.

Metal profiles with rigid structures and false ceilings and retaining walls or gypsum panels (Plasterboards) and PVC panels

The best examples of industrial construction are rigid constructions. Good seismic performance, easy and fast implementation, high accuracy, and reduction of dead load are the benefits of...

Galvanized profiles for reinforcement of UPVC profiles

The steel reinforcement sections inside UPVC door and window profiles are one of the most important aspects of these doors and windows. Such that, based on the...

Yaran Bahar Golestan is a famous brand in the galvanizing industry

Yaran Bahar-e Golestan Co launched the roll forming unit in the second decade of its activities.

Roll forming is one of the most common methods of shaping metal sheets. In this method, the sheets are shaped after passing some reels (templates) along their way. In Roll forming method, the bindings and angles imposed on the sheets at different stages of forming, should apply the lowest stress on the produced sheets or profiles so that desirable and admirable structures may yield, and the possibility of change may be reduced to minimum on considerable lengths of sheets. The number of stages or so called stations of roll forming device depends on the type of sheet, its form and thickness and the complexity of the structure’s angle.

Information

Contact Us

Sarv 6 St -Gonbad kavous Industrial Park - Gonbad Kavous - Golestan - Iran

![]() 017 33261380-85

017 33261380-85

![]() 017 33261380 (x6)

017 33261380 (x6)

![]() 09111720441 - 09113721095

09111720441 - 09113721095

![]() 09112764605

09112764605